ROmiLL AGRICULTURE

Czech-Built Feed Production and Grain Processing Technology

Designed and manufactured in the Czech Republic since 1991, ROmiLL AGRICULTURE produces innovative wet grain crushers, stationary grinders, feed mixers, and complete post-harvest processing solutions. With over 30 years of engineering expertise and machines operating in 38 countries worldwide, ROmiLL delivers exceptional performance for livestock farmers, agricultural cooperatives, and industrial feed producers.

30+

Years Experience

38

Countries

Worldwide

60t/h

Max Crushing

Capacity

100+

Feed

Mill Projects

- AVAILABLE: Czech Republic

- Full Sales, Service & Parts Support

The ROmiLL Legacy

ROmiLL was established in 1991 as a limited liability company in the Czech Republic, taking over projects from a state research institute in two key areas: agricultural technology and industrial microwave heating. From the beginning, the company focused on developing innovative solutions for feed production and grain processing.

The company is the first Czech manufacturer of roller machines designed specifically for feed production. In 1992, they produced their first 300 series machine, followed by the high-performance 900 series prototype in 1993. Their breakthrough came in 2002 when they designed and manufactured their first mobile wet grain crusher, revolutionising how farmers process grain for livestock feed.

Today, ROmiLL AGRICULTURE operates from their production facility in Bohuslavice, near Kyjov, manufacturing stationary grinders and crimpers, mobile wet grain crushers, horizontal feed mixers, and machines for collecting round bales. They have completed over 100 implementations of post-harvest lines and feed production systems across Europe and beyond.

- Czech Engineering Excellence -All machines designed and built in the Czech Republic

- Global Distribution Network - Sales representation in 22 countries

- Development and innovation - In the field of feed processing and storage of cereals

Key Features & Benefits

ROmiLL machines are engineered for farmers, agricultural cooperatives, and industrial feed producers, delivering efficient grain processing with cost savings of up to 40 EUR per tonne compared to traditional drying methods.

Roller Mill Technology

Advanced crushing rollers ensure a homogeneous feed structure with minimal dust content, which improves digestibility and livestock production efficiency. Unique system of protection of the rollers against damage (former company patent).

Cost Savings

Save up to 40 EUR per tonne compared to grain drying. Wet grain processing eliminates expensive drying equipment and energy costs.

High Capacity

Throughput up to 60 tons per hour with the M2 PLUS, capable of covering the work of up to three combine harvesters simultaneously.

Adjustable Feed Texture

Variable feed structure from very fine feed for monogastric animals to coarse crushed grain for ruminant nutrition, all adjustable on the same machine.

Preservative Application

Integrated preservative application system ensures perfect mixing of grain with preservative for optimal storage and feed quality.

Year-Round Operation

Machines work as wet grain crushers during harvest season and as dry grain grinders throughout the year without changing working rollers. With a special adapter, it is possible to bag e.g. sugar beet pulps or brewer’s malt.

ROmiLL Equipment in Action

ROmiLLProducts

Choose from ROmiLL’s comprehensive range of wet grain crushers, stationary grinders, feed mixers, and complete post-harvest solutions for farms and industrial feed production.

Mobile Wet Grain Crushers with Screw Conveyor

M1

Performance matches the output of one harvester, with a stationary electric version available for biogas use, delivering up to 20 t/h with a 60 hp tractor.

0,4 - 0,5 l/t

Tractor min. 60 hp

2,960 kg

3,1 m³ Hopper

M2

A 9 m³ hopper is filled from the harvester or transfer truck, with space for four barrels (800 L) and a built-in hoist. It delivers up to 40 t/h with a 120 hp tractor, matching the output of two harvesters.

0,4 - 0,5 l/t

Tractor min. 120 hp

5,600 kg

9 m³ Hopper

M2 Plus

Highest-performance mobile crusher with stainless steel screw conveyor. 10m³ hopper for extended field operation. Covers three harvesters.

45-60 t/h

160HP Tractor

10m³ Hopper

1200mm Rollers

Mobile Wet Grain Crushers with Press-Tunnel

CP1 Little

Compact wet grain crusher ideal for smaller farms. Features 600mm rollers with press-tunnel options of 1.2m or 1.5m diameter. Favourable price with lower weight of 1,820kg.

8-15 t/h

70HP Tractor

2.8m³ Hopper

1,820kg

2 Operating Roller- 600mm

CP1 Simple

A simpler version of the CP1, ideal for medium-sized farms, designed for front loader filling. Available with 1.2 m or 1.5 m pressing tunnels, it delivers up to 20 t/h with a 100 hp tractor.

2,030 kg

100HP Tractor

3.7m³ Hopper

2 Rollers - 900mm

CP1

Versatile mid-range crusher for farm work. Features 900mm rollers with press-tunnel options of 1.2m, 1.5m or 2m. Perfect balance of capacity and maneuverability.

15-20 t/h

100HP Tractor

3.7m³ Hopper

2 Rollers - 900mm

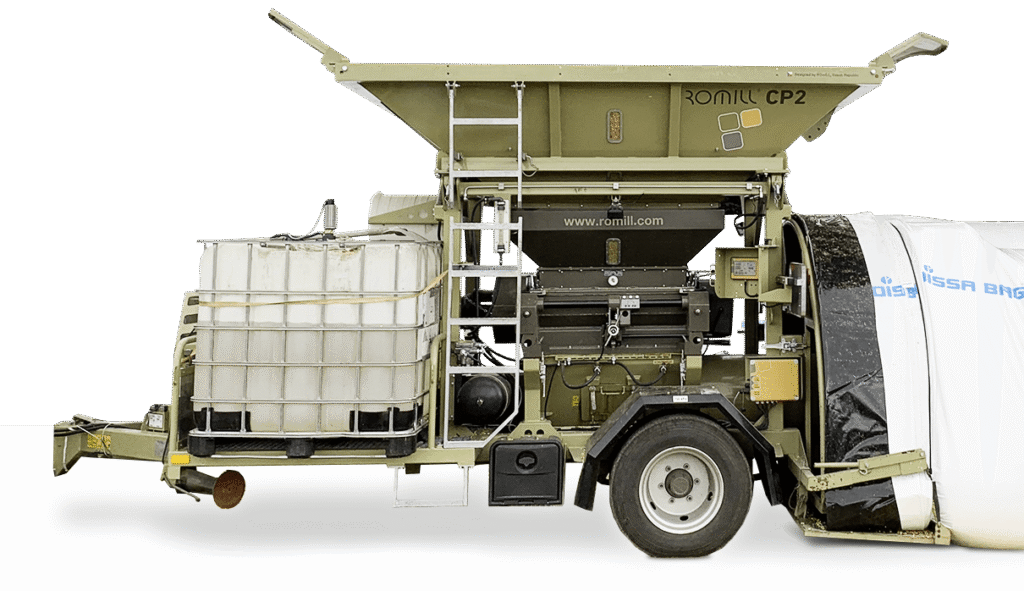

CP2

High-capacity crusher for contractors and larger operations. Dual crushing units with 4 rollers. IBC barrel space for preservative directly on machine.

30-40 t/h

160HP Tractor

3.4m³ Hopper

4 Rollers

CP2 Plus

ROmiLL’s most powerful crusher with 1200mm rollers. Covers work of up to three harvesters. Press-tunnel options: 1.5m, 2m, 2.4m or flexible tunnel.

45-60 t/h

200HP Tractor

10m³ Hopper

4 Rollers

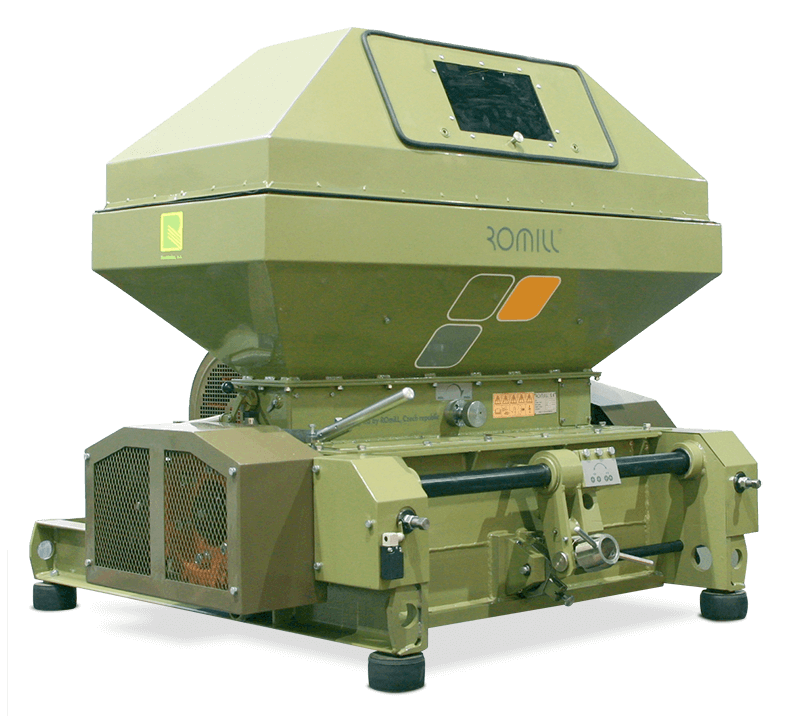

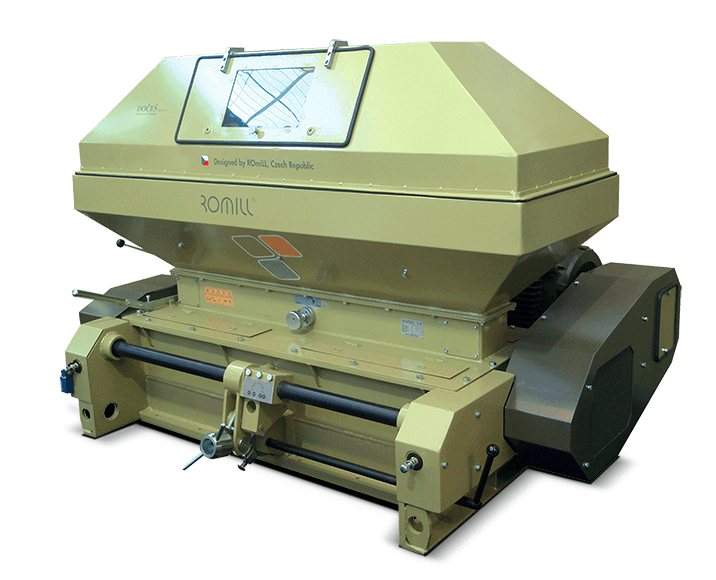

Stationary Roller Grinders

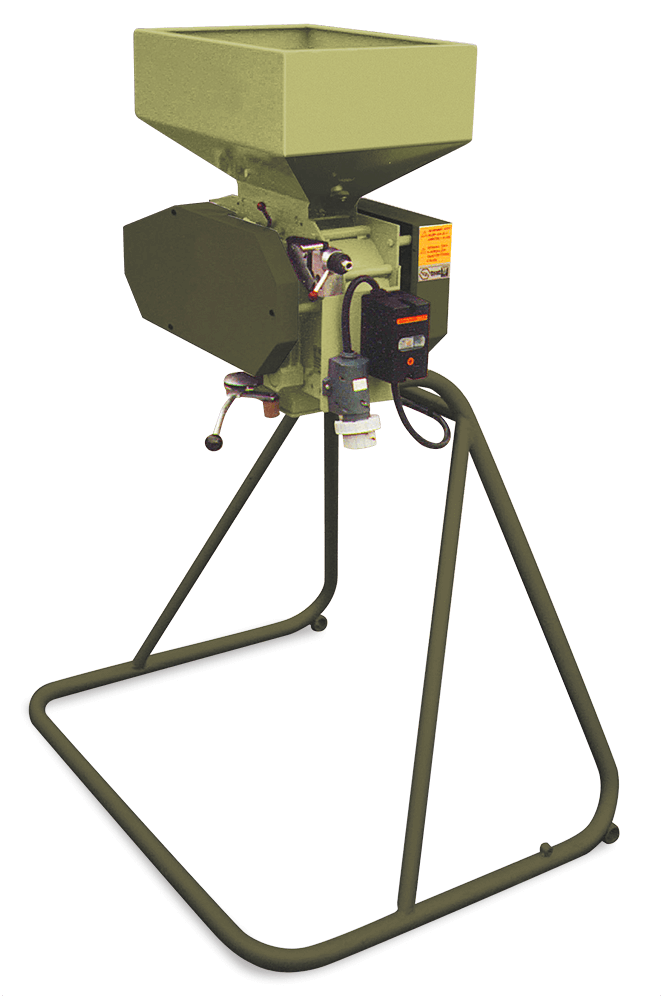

S100 Roller Grinder

The smallest roller grinding mill bruiser (100 mm rollers) is ideal for small farms, available with a stand, hopper, bagging unit, and basic wiring.

163 kg

100mm Rollers

Electric Motor 2,2 kW

For dry grain

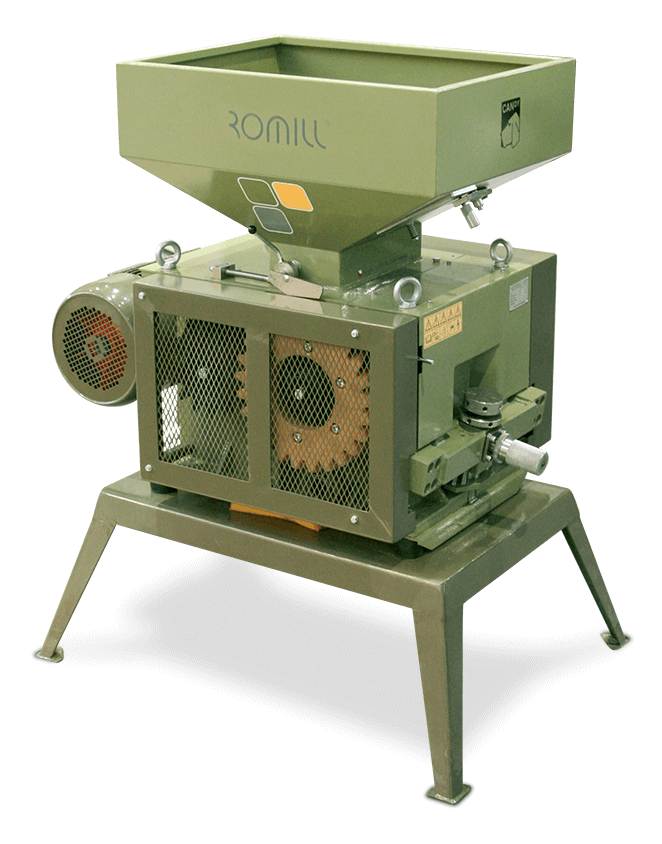

S300 Roller Grinder

Compact stationary grinder with 300mm roller length. Ideal for smaller farms and feed production operations. Energy savings up to 70 percent for coarse crushing.

1.2-2.6 t/h

300mm Rollers

Electric Motor

Low Dust

S600 Roller Grinder

A 600 mm roller grinding mill bruiser for farms of any size, supplied with a hopper. Hopper cover, magnet, and wiring panel are optional.

993 kg

600mm Rollers

3 × 400V, 50 Hz -18,5 kW

S900 Roller Grinder

High-performance stationary grinder with 900mm roller length. Suitable for medium to large agricultural companies and cooperatives.

7-20 t/h

900mm Rollers

Industrial Grade

Homogeneous Output

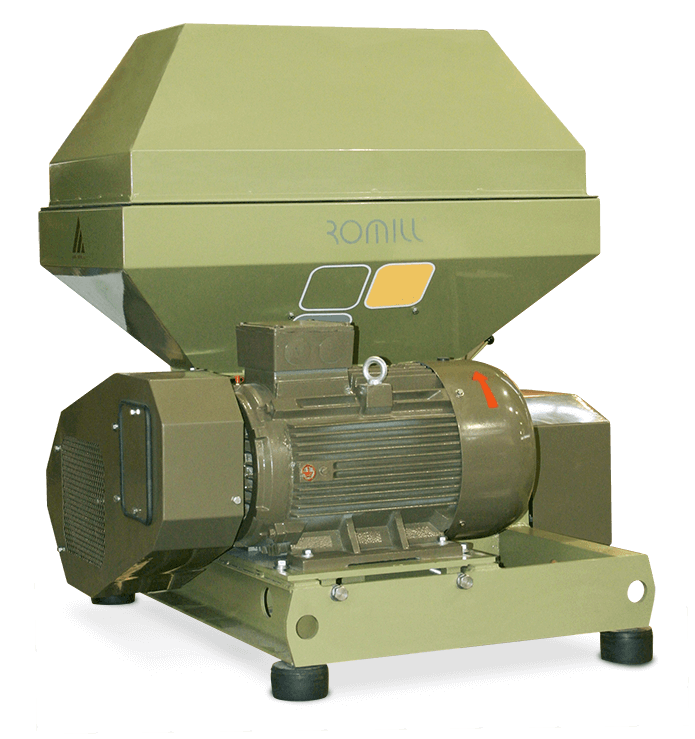

S1200 Roller Grinder

ROmiLL’s highest-performance stationary grinder with 1200mm rollers. Designed for industrial-scale feed mixture producers.

Coarse grinding - 17 - 25 t/h

1 712 kg

1200mm Rollers

Fine grinding 10 - 12 t/h

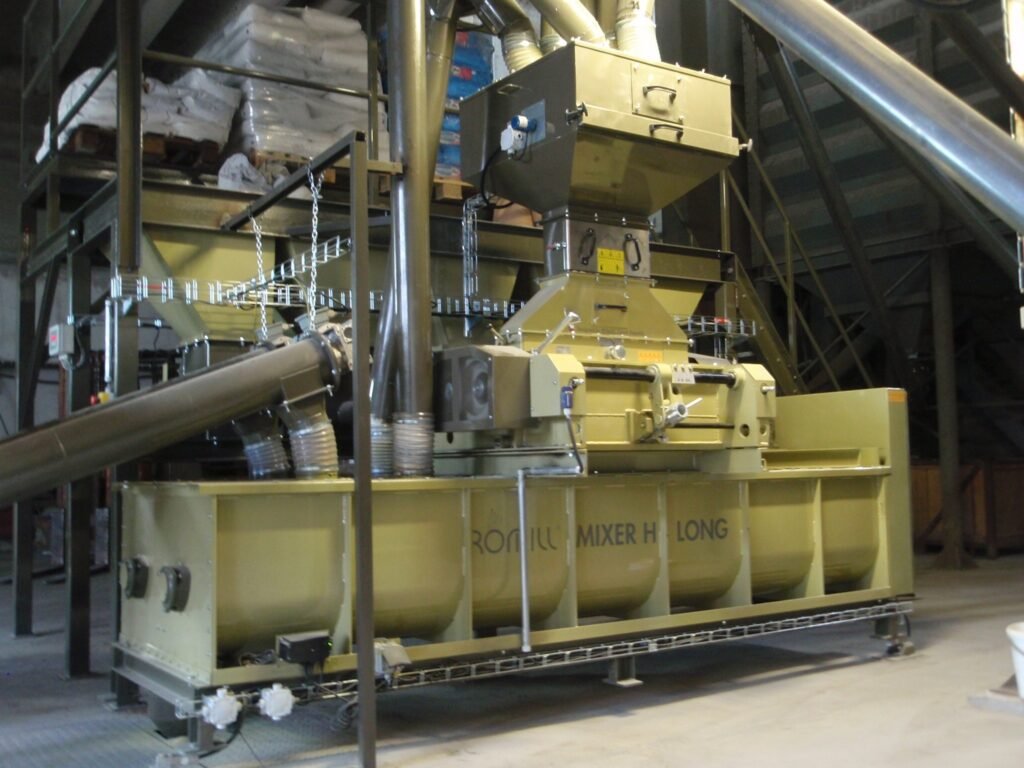

Feed Mixers and Complete Systems

MIXER H Horizontal Feed Mixer

Twin-rotor horizontal mixer with accuracy higher than 1:10,000. Two counter-wound spirals provide intensive mixing. Starts even when chamber is filled.

1:10,000 Accuracy

Twin Rotor

Low Height

Stainless Option

Industrial Feed Mills

Complete turnkey feed production systems. Compact and variable assemblies with fully automatic control. Single operator handles entire operation including distribution.

800-10,000 t/year

Fully Automatic

Turnkey Solution

3 Shift Operation

Post-Harvest Lines

Complete grain storage and processing solutions including silos, conveyors, cleaners, and handling equipment. From design through installation.

Privé Silos

Denis Conveyors

LODA Hoppers

Complete Design

Bale Handling and Transport

ROTOS Round Bale Handler

Unique self-loading round bale handler for efficient collection and transport of bales. Handles various bale sizes with ease.

Self-Loading

Various Sizes

Efficient Transport

Tractor Mounted

Farmbagger Profi

Professional silage bag filling machine with 5.5m³ bunker capacity. Performance of 250-300 tonnes per hour for efficient grain storage.

250-300 t/h

5.5m³ Bunker

2,220kg Weight

20km/h Transport

Why ChooseROmiLL Equipment

30 Plus Years Experience

First Czech manufacturer of roller mills for feed production, with proven reliability since 1991.

Versatile Applications

Same machine processes wet grain in harvest and dry grain year-round without changing rollers.

Significant Cost Savings

Save up to 40 EUR per tonne compared to traditional grain drying methods with wet grain processing.

Complete Solutions

From individual machines to complete turnkey feed mills and post-harvest lines with full support.

Improved Feed Quality

Roller mill processing increases digestibility and production efficiency compared to hammer mills.

Global Support Network

Sales representation in 22 countries with machines operating across 38 countries worldwide.

ROmiLL Equipment Video

Get in Touch About

ROmiLL Equipment

Whether you are looking for a new ROmiLL wet grain crusher, stationary grinder, complete feed mill solution, or need spare parts and service support, our team is here to help.